| Technology | Model /Series | Gas Flow | Liquid Flow | Steam Flow | Line Size | Temperature | Pressure | Viscosity | Accuracy | Considereations |

| DP Meters | ALDP | Must Include DP Transmitter |

The versatile ALDPT line of pressure/differential pressure transmitters from SmartMeasurement is suitable for a wide array of pressure measurement applications. This product may be configured as a gauge pressure transmitter, an absolute pressure transmitter, a differential pressure transmitter, a tank level indicator that reads directly in units of inches/feet/mm/cm, or a flow meter when used in conjunction with a primary flow element such as the SmartMeasurement ACONE. A wide range of accesories and process connections such as two, three, or five vlve manifolds, capilliaries for remote installation, and ANSI, DIN, JIS, Code 61/Code 62, or NPT threaded process connections make the ALDPT pressure transmitter adaptable to virtually any industrial application.

Features

| Technology | Model /Series | Gas Flow | Liquid Flow | Steam Flow | Line Size | Temperature | Pressure | Viscosity | Accuracy | Considereations |

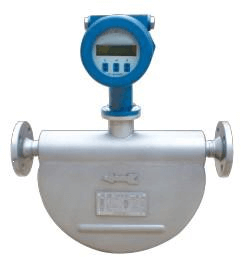

| Coriolis | ALCM | Avoid Vibration |

SmartMeasurement is ALCM family of coriolis flowmeters are offered in three different tube geometries to accomodate virtually any flow measurement application. The ALCM-UT, which employs the well-known U-tube geometry, offers wide turndowns and is an excellent choice for general purpose coriolis applications and replacement of existing meters having U-tube geometry. The ALCM-MB features a unique micro-bend tube geometry that provides lower pressure loss and superior drain-ability & clean-ability. For lower flow applications, the ALCM-DT makes use of triangular, or delta-shaped measuring tube.

Features

| Technology | Model /Series | Gas Flow | Liquid Flow | Steam Flow | Line Size | Temperature | Pressure | Viscosity | Accuracy | Considereations |

| Magnetic | ALMA |

Conductive Fluids Only |

Smart measurement offers a complete line of mag meters to deal with any application where a mag meter may be used. For general purpose applications, the ALMAGWP products is offered in 3/8~120″(10-3000mm)nominal size and offered with a wide variety of choices of materials for the meter liner electrodes.

Features

SmartMeasurement ALSONIC Series flowmeters offer tue non-invasive flow measurement by utilizing the proven transit-time ultrasonic method which employs transducers that clamp on the outside of the pipe. The clamp on installation makes installation dramatically more simple and economical vs. traditional in-line style meters.

Features

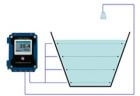

Energy Flow Meters Overview: Flowmeters that perform energy measurement consist of a flowmeter with integrated temperature measurement to measure both supply and return temperature and then calculate thermal energy in units of BTUs. In addition to providing direct BTU measurement, these flowmeters also can display liquid flow rate and process temperature. The temperature measurement is typically achieved via use of precision RTD elements while the liquid flow rate measurement can be done with an electromagnetic flowmeter, a turbine flowmeter, an ultrasonic flowmeter, or a variety of other flowmeter technologies.

SmartMeasurementTM offers Energy flow meters that employ ultrasonic and magnetic flow measurement technologies in order to provide users with a degree of flexibility in selecting the best product for their specific application. For non-intrusive energy measurement, the ALSONIC-EG provides highly accurate energy measurement for applications including treated water with low electrical conductivity and buildings where the air-conditioning can’t be turned off to install the meter. The ALSONIC-EG enables retrofitting of transducers under pressure with a clamp-on non-intrusive installation method. For applications where there are particulates or bubbles entrained in the fluid, the ALMAG-EG, which makes use of a Mag Meter to measure the liquid flow, is the instrument of choice. All SmartMeasurement BTU Flowmeters are available with optional Mbus, BACNET, MODBUS, and Profibus communication protocols.

Most traditional flow metering technologies, such as turbine meters or positive displacement meters, employ volumetric techniques. This means that the meter output or displayed value on the screen is in volumetric units of measure, such as GPM or LPM. There are a number of flow measurement applications that require the flow rate to be measured in mass units, including chemical mixing/batching, custody transfer, and emissions monitoring. Making use of volumetric flowmeters in these applications can prove to be challenging because converting the volumetric units to mass units requires the volumetric reading to multiplied by a media density value. For liquid fluid media, the density value changes with temperature; for gas media the density changes with both temperature and pressure. The changing density leads to inaccuracy when volumetric meters are applied in these situations. Mass Flowmeters solve this problem by providing a direct mass flow reading which is immune to changes in process temperature and pressure.

SmartMeasurement offers two Mass Flowmeter technologies. The ALCM Series of Coriolis Mass flowmeters is ideal for liquid flow measuring applications and is available for line sizes ranging from ½” through 8” and flow rates ranging from 150 to 1,000,000 kg/hr. For compressed gas applications, the ATMF line of Thermal Mass flowmeters is available in both in-line and insertion versions to accommodate line sizes ranging from ¼” to over 30”.

Smart Measurement’s ALSONIC-AVM system is an open channel flow meter that works as an area-velocity meter in conjunction with a user-supplied level transmitter to measure flow rates in open channels. The ALSONIC-AVM consists of an advanced DSP-based flow computer and four transducers, with the transit time difference of ultrasonic sound pulses being used to measure the open channel flow velocity. The ultrasonic pulses are transmitted upstream and downstream across the channel at an angle between the flow direction and the sonic wave path; the difference in the sonic wave’s transit time is directly proportional to the liquid velocity.

The ALSONIC-AVM may be used in rectangular, circular, trapezoidal, or other shaped channels. Since the transducers create almost no restriction, virtually no head loss is created. The advanced DSP-based flow computer with cross-correlation and FFT technology allows this system to work in the most difficult applications, including those involving liquids with high concentrations of suspended solids and air or a large noise component.

Measuring the flows of viscous fluids demands a flow meter that provides a high degree of repeatability, linearity, and immunity to changes in viscosity that will occur as the fluid temperature changes. These requirements make the positive displacement(PD) meter the flowmeter of choice for viscous fluids. SmartMeasurement offers avariety of positive displacement meters to accomodate line sizes ranging from 1/4″ to 10″(6-250mm) and flow rates from a low as 0.13 to 7900 GPM (0.03-1800cubicmeter/hr). Applications include custody transfer, chemical injection, batching, and well output monitoring.

Features

Thermal mass flowmeter are an ideal choice for monitoring the flow rates of air and other compressible gasses because they provide a direct-mass flow measurement of the following gas. The mass flow measurement is unaffected by changes in the gas pressure or temperature and therefore does not require any compensation for these codition as would a mechanical meter such as turbine or variable area meter. These versatile instruments provide users with the ability to read mass flow rates, volumetric flow rates, and process temperature with a single meter.

Features

The ALTM Series of turbine flowmeters are used for the precise measurement of instantaneous flow rates of low viscosity fluids such as tap and demineralized water, fuels, liquified gasses. This meter uses the long-proven axial turbine technique for measuring flow rates. A low mass turbine wheel carried concentrically within the flow body where the fluid flows rotates axially, where the RPM of the turbine wheel is directly proportional to the mean velocity of the fluid.

Features

| Technology | Model /Series | Gas Flow | Liquid Flow | Steam Flow | Line Size | Temperature | Pressure | Viscosity | Accuracy | Considereations |

| Variable Area | ALVAMT |

Conductive Fluids Only |

Features

Vortex meters are one of the few flow measuring technologies that can measure all three phases of a fluid; gas, liquid and steam. This technology provides a cost-effective, reliable, low maintenance solution for many flow measurement applications. It has no moving parts, therefore no routine maintenance or cleaning is required. The vortex flowmeter can measure also measure wet and/or dirty gases. Vortex flow sensing technology relies on measuring the number of vortex pulses generated by a bluff body immersed in the flow stream. A bluff body is machined inside the vortex flow meter; as flow pass through this bluff body, vortices are generated in either side of the bluff body. The flow rate can be determined by measuring the number of vortices.

The design of SmartmeasurementTM‘ s ALVT vortex flowmeter allows for extremely wide turndowns while maintaining an almost unlimited upper end as well as a high pressure rating. The ALVT can be configured in inline styles with both NPT and flanged connections or as an insertion meter with optional hot-tapped ball valve mounting for installation and/or removal of the instrument without shutting down the process. Our ALVT-MASS multivariable vortex flow meter incorporates an RTD temperature sensor and a solid state pressure transducer that allows the mass flow rate of steam, gases and liquids to be measured and displayed directly on the meter’s display. Please see the Vortex flowmeter matrix below to view all available options.