Product Description

Gas valve, with square or rectangular damper design.

Unidirectional guillotine damper.

Various seat and packing materials available.

Face‐to‐face distance in accordance with CMO standard.

Use

This guillotine damper valve is suitable to work with a large range of airs and gases

It is particularly suitable as an isolation element in order to allow inspections, maintenance and repairs in the ducts.

Working Pressure

Maximum standard work pressure is 0.5 kg/cm 2 ; greater pressures upon request.

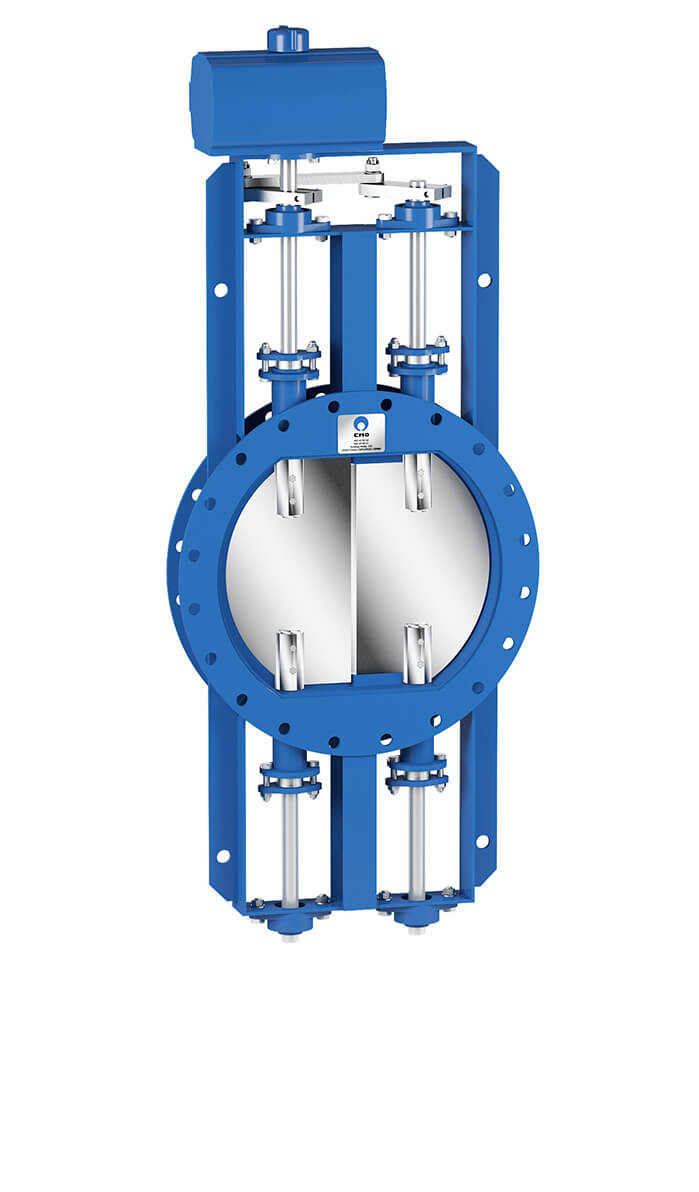

Product Description

Gas valve, with round damper design.

Unidirectional guillotine damper.

Various seat and packing materials available.

Face‐to‐face distance in accordance with CMO standard.

Use

This guillotine damper valve is suitable to work with a large range of airs and gases.

It is particularly suitable as an isolation element in order to allow inspections, maintenance and repairs in the ducts.

Sizes

From DN 150 up to DN 3000 (larger sizes on request).

Check with CMO for the general dimensions of a specific damper.

Working Pressure

Maximum standard work pressure is 0.5 kg/cm 2 ; greater pressures upon request.

Product Description

Round multilouvre damper butterfly valve, shutter type, with bidirectional design.

Designed for pneumatic transport of air or gases at different temperatures.

Option of manufacturing “WAFER” type or with bored flanges.

Watertight integrity between 97% and 99%.

Use

These multilouvre damper butterfly valves are suitable to work with a wide range of air and gases. They are particularly suitable for controlling the flow of gas in pipelines.

Sizes

From DN 400 up to DN 3000 (larger sizes on request). Check with C.M.O. for the general dimensions of a specific round multilouvre damper butterfly.

Working pressure

Maximum standard work pressure is 0.5 kg/cm2; greater pressures upon request.

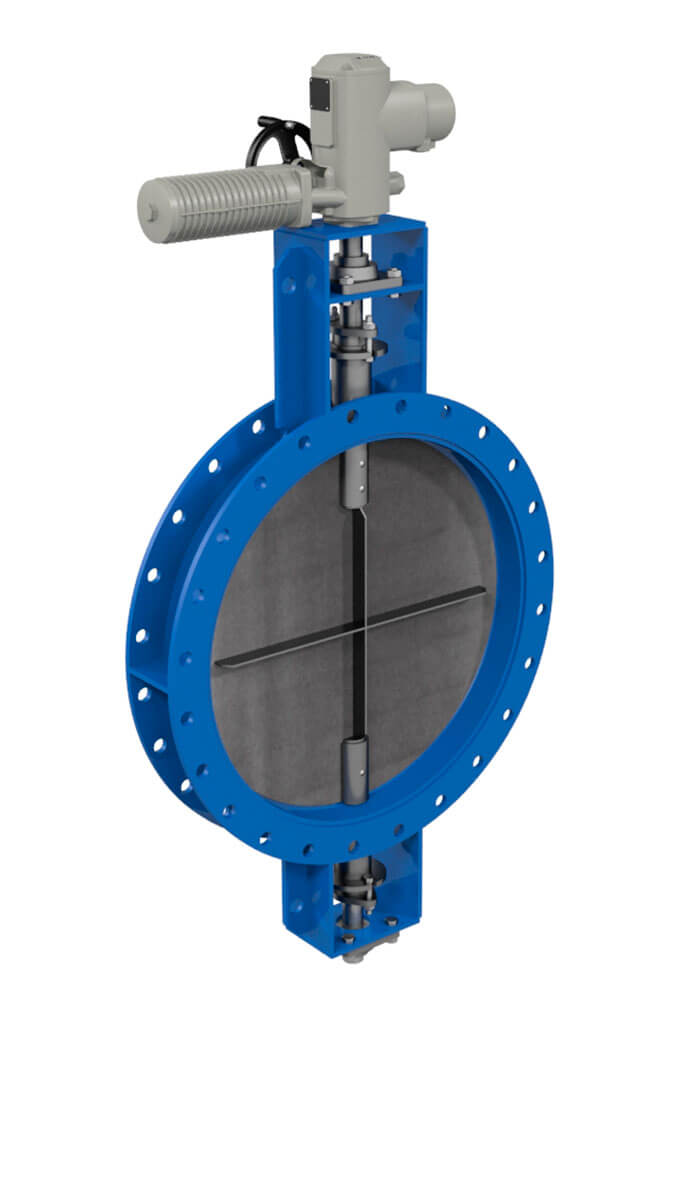

Product Description

Round damper butterfly valve, with bidirectional design.

Designed for pneumatic transport of air or gases at different temperatures.

Option of manufacturing “WAFER” type or with bored flanges.

Watertight integrity between 97% and 99%.

Use

The materials used for the fabrication of these Dampers MF depend on the temperatures and the working pressures.

These butterfly damper valves are suitable to work with a wide range of air and gases. They are particularly suitable for controlling the flow of gas in pipelines.

Sizes

From DN 80 up to DN 3000 (larger sizes on request). Check with C.M.O. for the general dimensions of a specific damper butterfly.

Working (ΔP)

The most significant difference between the ML and MF series is the differential working pressure (ΔP).

For lower pressures, choose the ML series (Light Butterfly); for higher pressures, choose the MF series..

Maximum standard work pressure is 0.5 kg/cm2; greater pressures upon request.

Product Description

Round damper butterfly valve, with bidirectional design.

Designed for pneumatic transport of air or gases at different temperatures.

Option of manufacturing “WAFER” type or with bored flanges.

Watertight integrity between 97% and 99%.

Use

The materials used for the fabrication of these Dampers MF depend on the temperatures and the working pressures.

These butterfly damper valves are suitable to work with a wide range of air and gases. They are particularly suitable for controlling the flow of gas in pipelines.

Sizes

From DN 80 up to DN 3000 (larger sizes on request). Check with C.M.O. for the general dimensions of a specific damper butterfly.

Working (ΔP)

The most significant difference between the ML and MF series is the differential working pressure (ΔP).

For lower pressures, choose the ML series (Light Butterfly); for higher pressures, choose the MF series..

Maximum standard work pressure is 0.5 kg/cm2; greater pressures upon request.

Product Description

Round-port isolating valve triple lever system operated.

Use

For gaseous clean fluids as air, nitrogen, oxygen and gaseous dirty fluids carrying suspended solids.

Sizes and custom

Dimensions, materials, design pressure and tightness adapted to customer´s requirements Actuators: Pneumatic, Electric, Hydraulic…

Product Description

The louver damper is composed of various blades which each turn on the central shaft. The ends are joined to the pipes via flanges. Normally, the louver damper is supplied as one piece, except in those applications in which the dimensions of the equipment require special transport.

Construction

The body of the PL damper is machine welded and can be made of different materials. The standard construction sizes range from 150×150 mm (minimum) to 3000×3000 mm although larger sizes are available on request. The blades are made flat, with reinforcing ribs and are supported on two semi‐shafts. The flat blade system is sufficiently rigid for the working pressures of these valves and they do not produce significant load losses.

Sealing Systems

The PL dampers have two types of seals. Depending on the application you can choose between: Swing‐thru (97% seal), for environments with high dust concentrations, the metal/metal seal (99% seal) and the step‐seat joint for other applications that require greater watertight integrity, reaching 100% with air chamber sealing.

Bearings

CMO supplies its PL dampers with bearings fitted to the outside and separate from the packing. This ensures they are protected from heat sources and corrosion, extending their working life. This system also allows the packing to be changed without the need to remove the bearings, making future maintenance tasks easier.

Insulation

CMO supplies its valves ready for external insulation of 200 mm. In order to change the bearings and packing in the future without the need to remove the insulation, a space is left free for this purpose.

Product Description

The cleaner are automatic equipment installed on gates that protect pipelines, turbines, pumps, canals, ponds or reservoirs to ensure a low degree of clogging or by periodic cleaning depending on the operation, either by detecting the falling load passage of water through the grate.

It is common gate and limpiarrejas equipment design, manufacture and install simultaneously to ensure proper functioning of the whole.

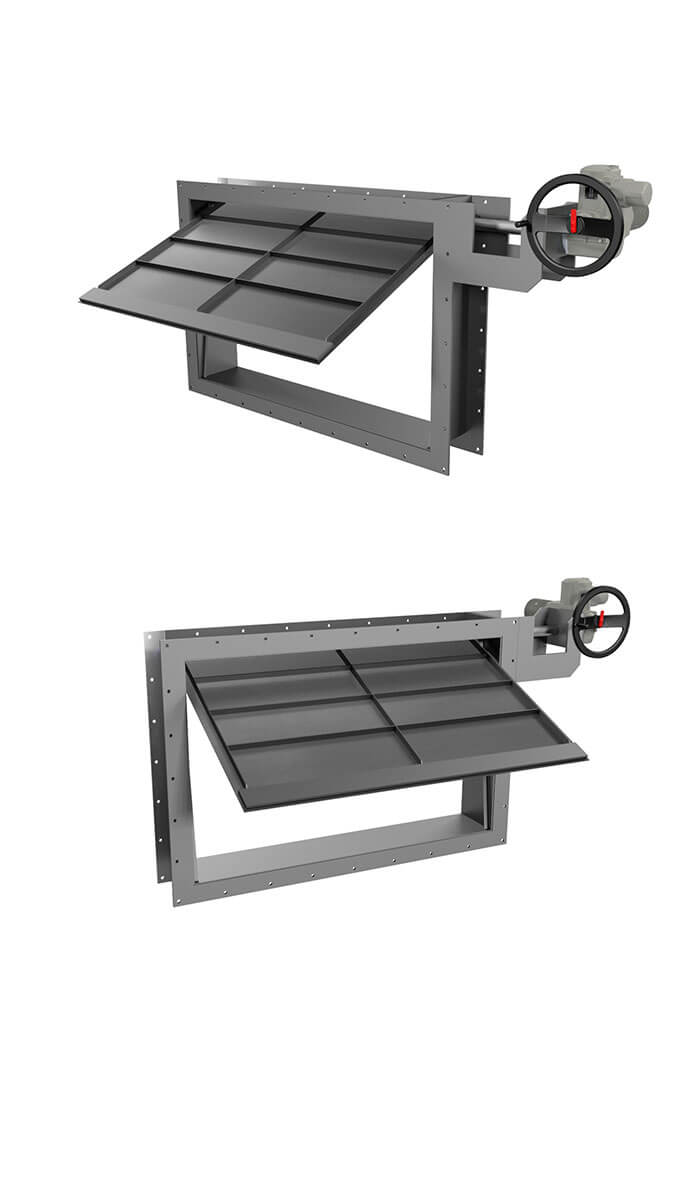

Product Description

The SC damper is composed of a blade which turns on a shaft located on one side (like a gate). The ends are joined to the pipes via flanges. Normally, the SC damper is supplied as one piece, except in those applications in which the dimensions of the equipmentrequire special transport.

Construction

The body of the SC damper is machine welded and can be made of different materials. The standard construction sizes range from 150×150 mm (minimum) to 3000×3000 mm although larger sizes are available on request. The blade is made flat, with reinforcing ribs and is supported on two semi‐shafts. The flat blade system is sufficiently rigid for the working pressures of these valves and they do not produce significant load losses.

Insulation

CMO supplies its valves ready for external insulation of 200 mm. In order to change the bearings and packing in the future without the need to remove the insulation, a space is left free for this purpose.